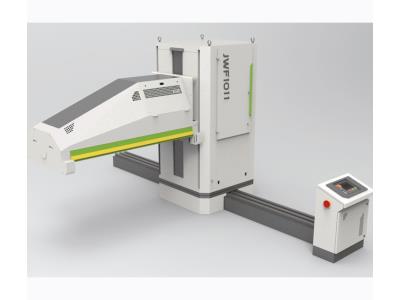

CARDING MACHINE

- Product Details

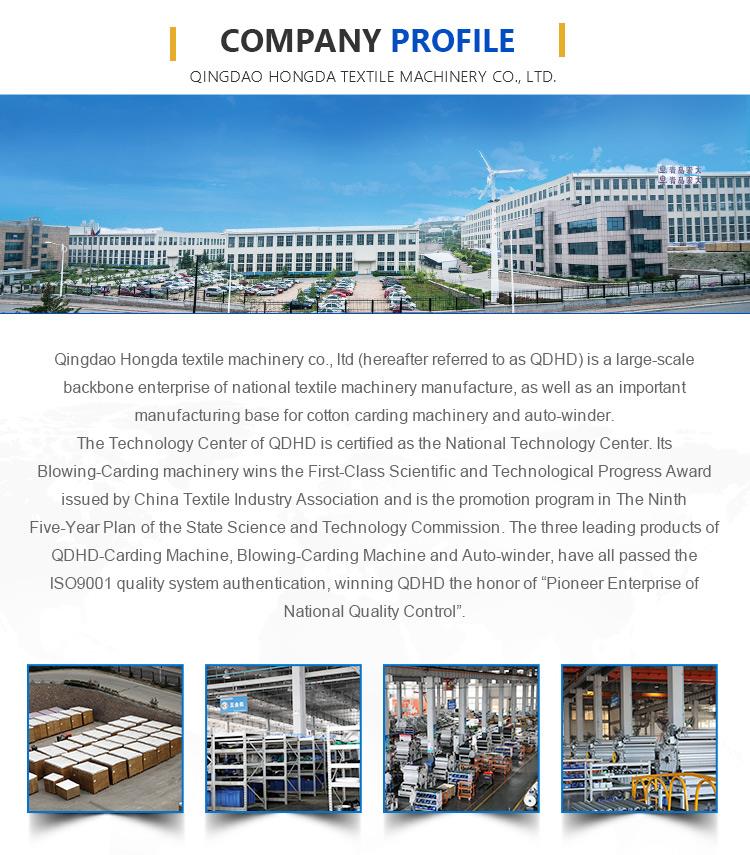

- Company Profile

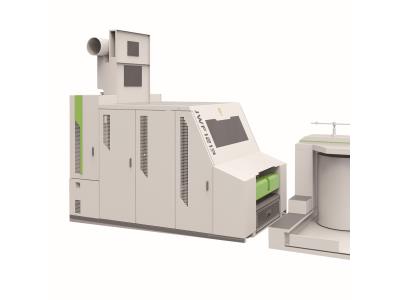

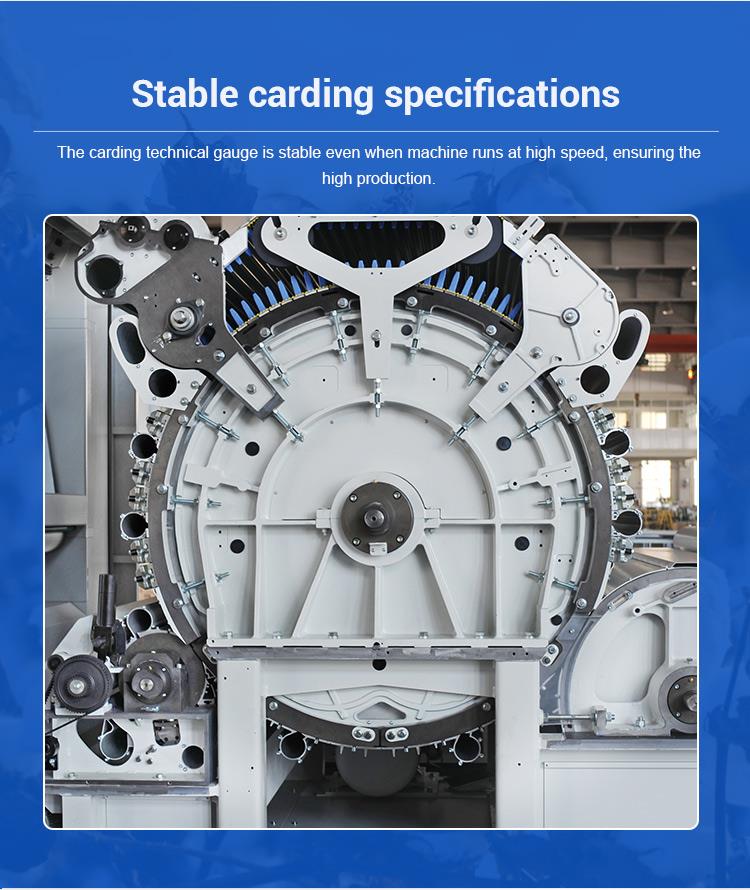

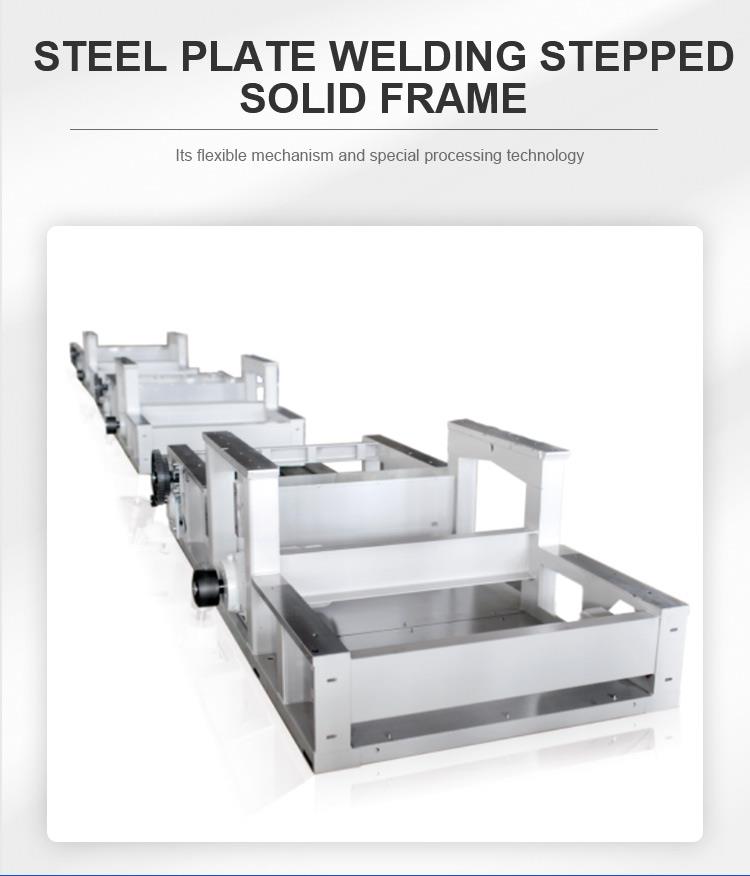

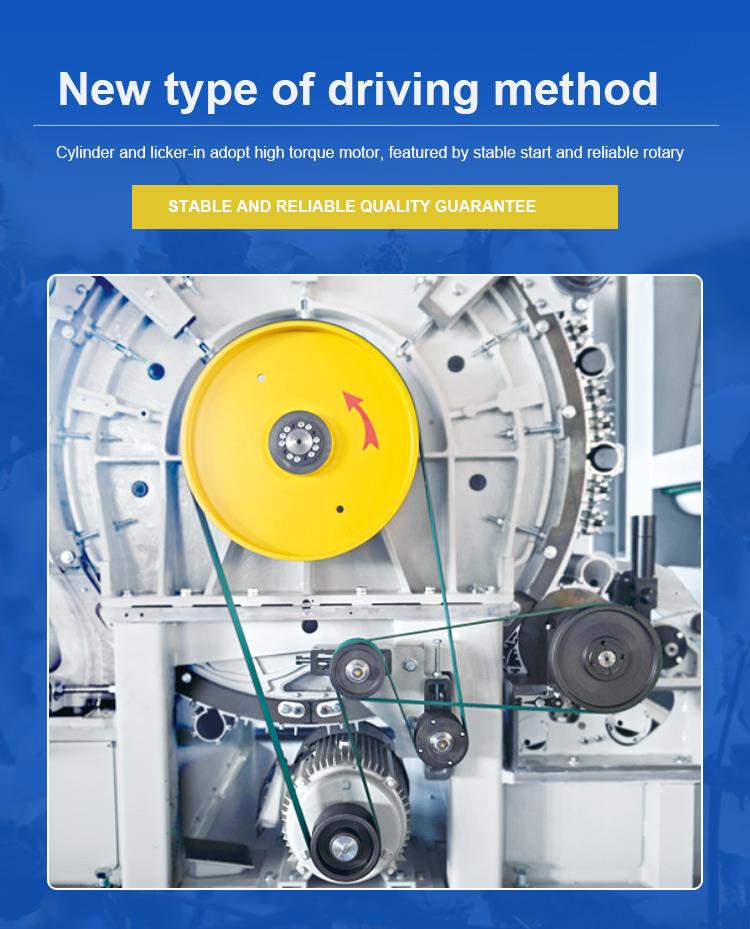

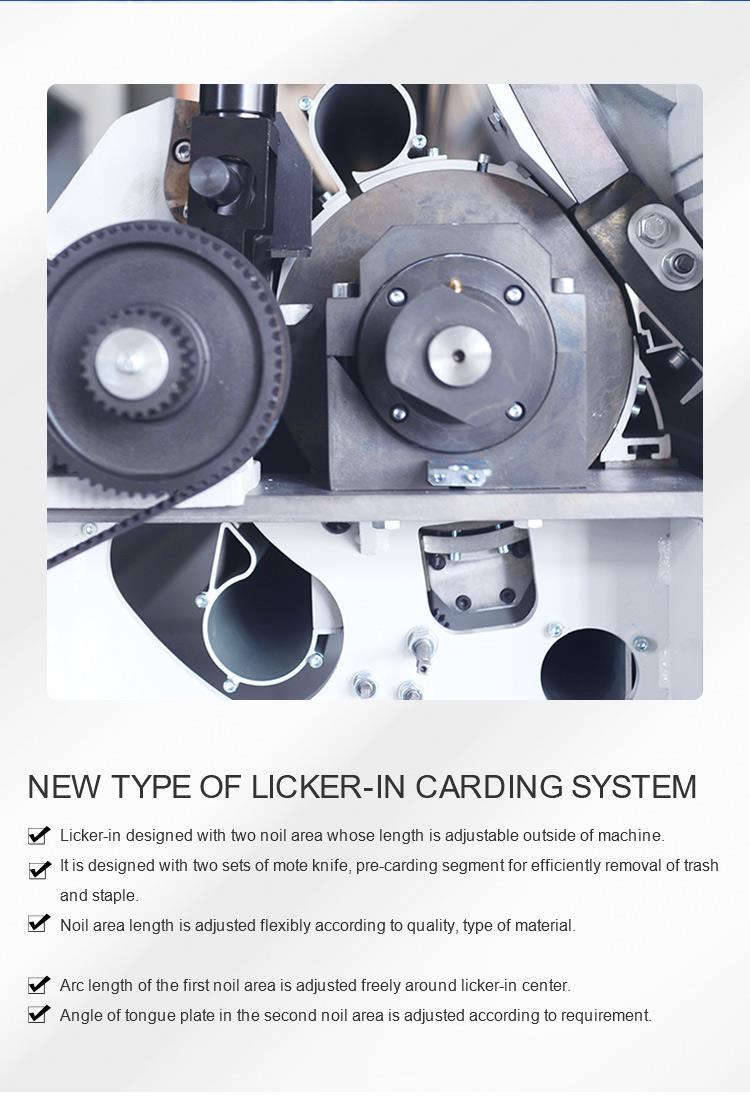

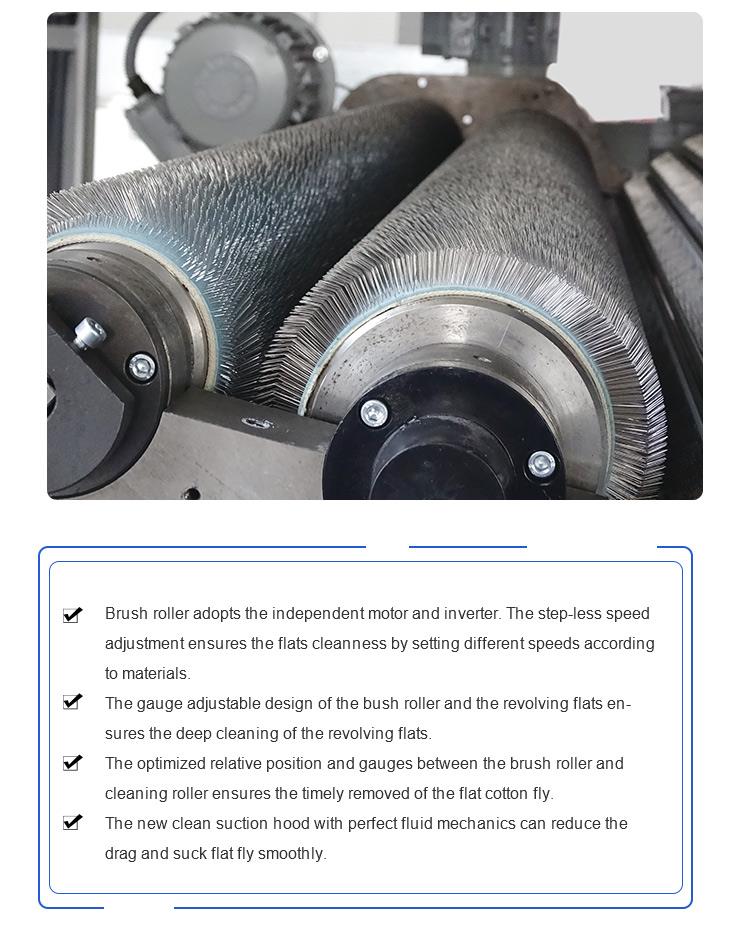

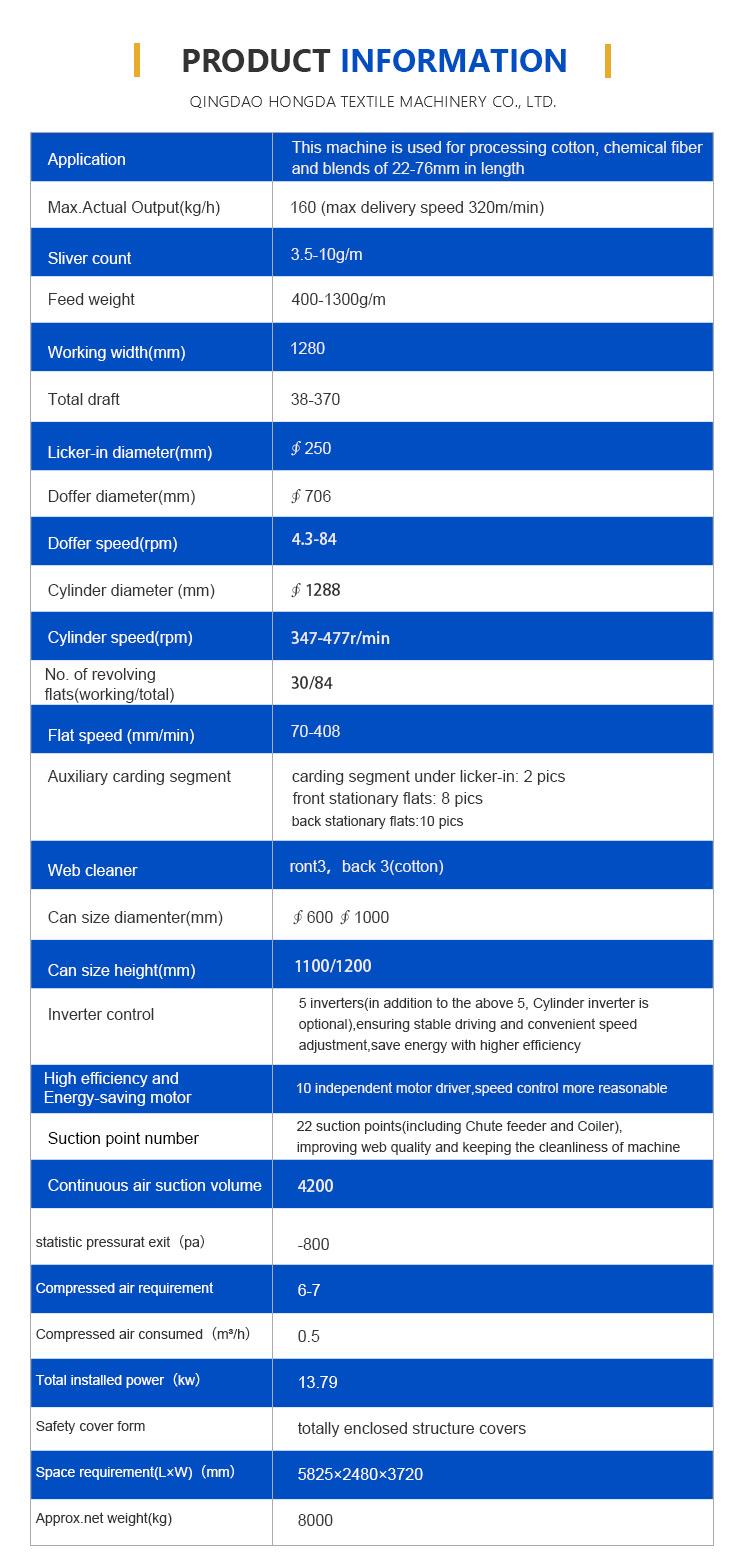

carding system with high production and efficiency stable and reliable quality gurantee new type of licker-in carding system dust filtering system modular design-easy operation and maintenance new type mixed loop auto-leveller system new type detecting and protecting system sliver-cutting without particular 6-points gauge and new type of cross apron

JWF1213A, which is a new product leads textile industrial structure adjustment and product upgrading has the characteristics of high yield, high efficiency, high quality and energy saving. A new generation of JWF1213A makes some creative innovation design, under the basis of widely accepted series of high production carding machine. The 1300 mm width design, cylinder, doffer and flat system was carried out on the key components, has a leading textile industry structure adjustment, product upgrade of new products. It has fully independent intellectual property rights and a number of innovative technologies, has authorized 13 patents for inventions and utility models. Also, it has adopted 12 patents owned by enterprises and the total number of its own patents has reached more than 30.Up to now, Qingdao Hongda has become a unique international carding manufacturer that can produce all series with the width of 1 meter, 1.3 meters and 1.5 meters, which can meet the needs of users for different types of spinning.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier