spiral concentrator Type H

- Product Details

- Company Profile

spiral concentrator Type H

Giving You Confidence

Giving You Confidence

As the world leader in spiral technology we provide you with unparalleled levels of confidence in the performance of gravity separation circuits.

We design, manufacture and supply the MD range of gravity separation equipment including spirals, shaking tables and slurry distribution and laundering systems.

Our Australian based head office houses the world's largest spiral manufacturing facility and produces over 20,000 starts annually. In 2010/11, we manufactured HC33 and WW6 spirals for ArcelorMittal's Mont Wright mining operations in Canada to deliver the largest single spiral order in our history.

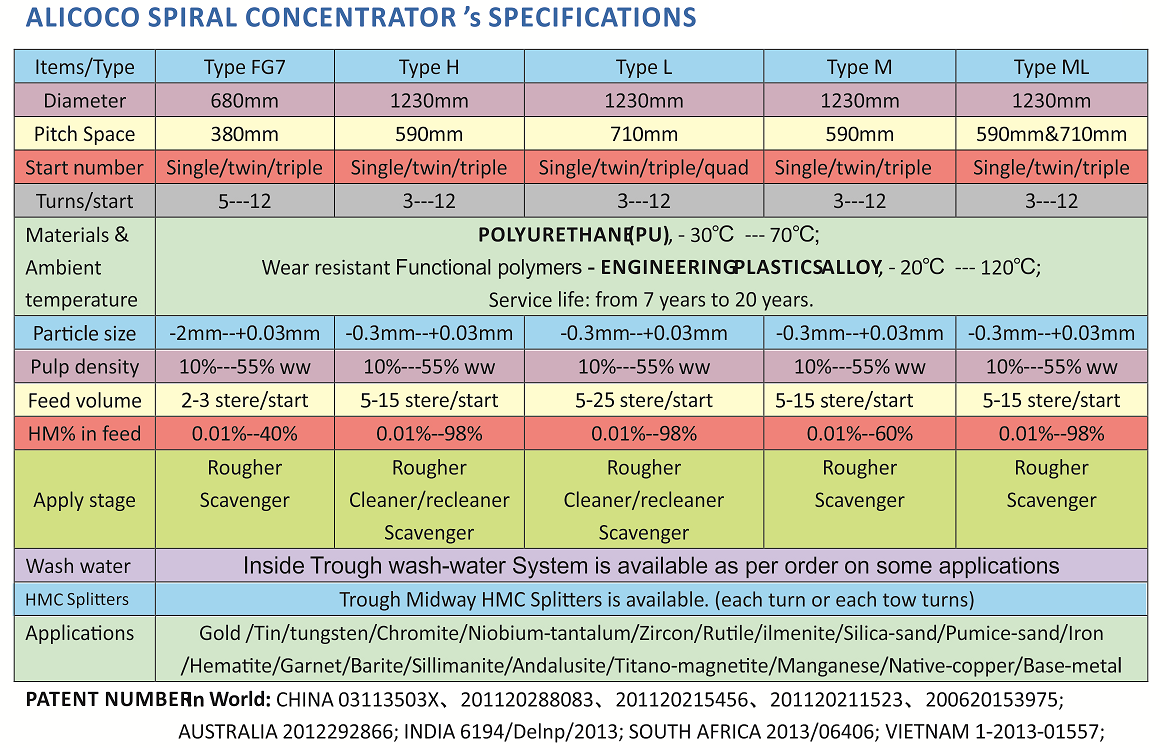

Features

1. Replaceable modular cast polyurethane feed box for positive feedline connection and longer spiral service life

2. Splitter configuration designed for each application

3. Concentrate diverter to obtain the highest concentrate product grade

4. Re-pulping devices to further enhance recovery and grade of product

5. Cast polyurethane product collector box ensuring long life and no splash collection system

6. Integrated engaged launder system

7. Accurate top or bottom entry feed distribution systems for improved recoveries

8. Simplicity of process circuits for reduced capital cost

9. Available with or without wash-water

Benefits

1. Spiral configurations in single, twin, triple and quad troughs per column to suit capacity requirements

2. Spiral banks up to 48 starts to maximize capacity and minimize floor space requirements

3. Low capital cost installations

4. Minimal maintenance requirements

5. Low operation cost and long operating life

6. Consistent separation efficiency with minimal operator attention

7. Comprehensive process engineering support

Applications

1. Rutile, ilmenite and zircon concentration

2. Iron ore, chromite and manganese beneficiation

3. Tin, Tantalum and tungsten ore concentration

4. Gold, native copper and base metal recovery

5. Silica sands processing and pumice sand separation

6. Titano-magnetite concentration

7. Garnet, kyanite, sillimanite and andalusite recovery

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier