double layer corrugated forming machine iron sheet making machine drywall metal roofing m

- Product Details

- Company Profile

double layer corrugated forming machine iron sheet making machine drywall metal roofing machinery

double layer corrugated forming machine iron sheet making machine drywall metal roofing machinery

Hot Sales

1. the advantage of double layer roll forming machine russis type

This kind of machine make two type of tile together perfectly, it has reasinable structure, beautiful appearance, with advantage of saving space, easy operate and especially welcomed by the costomer with limit area or site operation.

2. Main Parameter and specification of the russis type double layer roll forming machine

We design each machine according to user requirement. Below techinical parameters can be adjusted if needed.

1.control system: automatic PLC frequency control ,text screen.

2.roller steps:9/11 rows

3.main power:4kw

4.pump power:4kw

5.Diameter of roller: Φ72mm

6.max speed:12m/min

7.feeding width:1000mm

8.the effective width:850/840mm,tolerance ±1/100

9.thickness of the plate:0.35-0.6mm

10.the dimension of main roll former: 7600mm×1300mm×1450mm

11.roller material:45#steel,CNC-machined ,heat treatment, buffing, surface for electroplating chromium 0.05mm

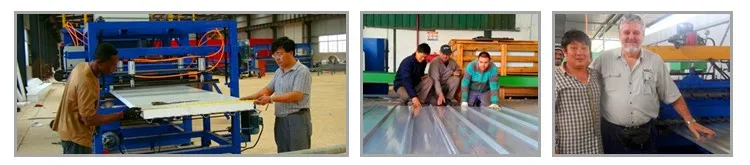

3.the picture of the russia type double layer roll forming machine botou

4.the profile drawing of the double layer roll forming machine:

the same as the picture or as the customer's requirement

5.Equipment components:

made uncoiler, Roll forming machine, computer control system, hydraulic control system, cutting

6.The usage of the doule layer roll forming machine

Our products are widely used in various industrial factory, civilian building, warehouse and easy steel building

manufacturing, and have features such as nice appearance and durable.

Packaging & Shipping

7.

Packaging Details: | Main machine is nude, the computer control box is packed with wooden frame. |

Main machine is nude in the container, the computer control box is packed with wooden packaging. | |

Delivery Detail: | 20 days |

Our Services

Guarantee:

12 Months guarantee. if some part of the machine is broken. we will supply the best part,but if the damaged parts due to operate error,buyer will pay for the shipping fee.

After-sale service:

We sent technician to your country to fix the machine.the buyer shoule bear all the cost includng:visa,roundtrip ticket and suitable accommodation,also buyer should pay the salary 100USD/DAY.

9.Company Information

Hebei Xinnuo Roll Forming Machine Co., Ltd., not only produce different types of professional roll forming machines, but also develop intelligent automatic roll forming production lines, C&Z shape purline machines, highway guardrail roll forming machine lines, sandwich panel production lines, decking forming machines, light keel machines, shutter slat door forming machines, downpipe machines, gutter machines, etc.

Our company locates in "The Town of Casting Molds", enjoys convenient transportation, with No. 104 & 106 National Highway and Jinghu-Shihuang High-Speed Way nearby.

Our machines feature beautiful appearance, long service life, good performance, simple operation, reasonable price, good quality and so on.

Strong technical resources are the most stable guarantee for our products' quality. We adopt computer software for design drawing, production drawing and installation drawing for steel construction equipment. We adopt advanced computer digital inspection and produce high quality light steel structure equipment. Our technical is updating day by day!

Our excellent and professional after-sales team will supply perfect services. We have a detailed manual book and can supply you with technical support via phone and network. If necessary, we can supply you with local technical support and send technicians to for installation and operation training.

FAQ

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier