Processing Machine Pellet Production Line

- Product Details

- Company Profile

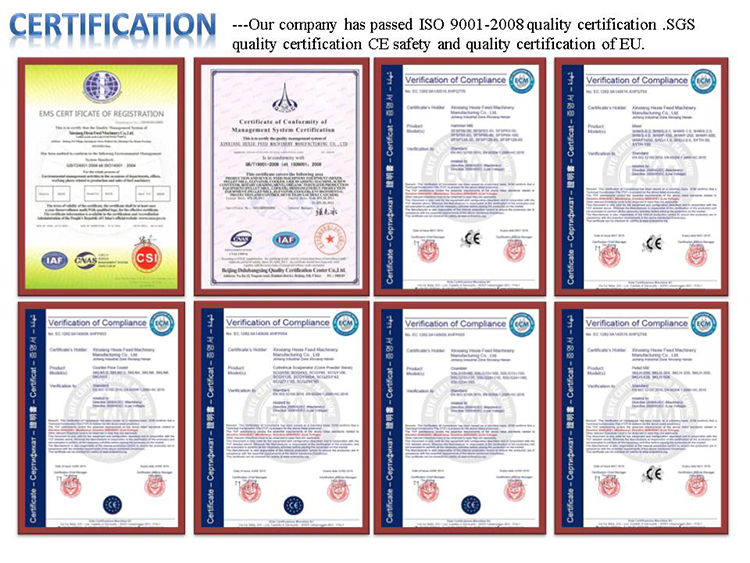

Basic Info Model No.: Feed Pellet Production LineType: Forage EquipmentCondition: New Additional Info Packaging: Standard Export Wooden CaseBrand: HEXIETransportation: Ocean,LandPlace of Origin: CHINACertificate: ISO9001Port: GUANGZHOU,QINGDAO,SHANGHAI

Processing Machine Pellet Production Line introduction

This type machine is specially used for making animal feed pellet for chicken ,pig duck , goose fish ,sheep ,cattle , horse , deer etc . Feed pellet increase the feed use rate and reduces waste .

It also can be used for making soft wood pellet ,organice fertilizer pellet . Widely used for home , small or medium farm and busineess .

It doesn't need or with a little liquid ,then can be making for granulation. Dry processing ,the production of feed particle high hardness ,smooth surface ,high temperature sterilization, internal curing ,can improve the digestion and absorption of nutrients .

Simple structure,wide adaptability ,covers a small area,low noise.High efficient and low consumption.The spare part with wear-resistant alloy steel material after heat treatment , it have more long service life , pellet diameter can be select according your require .

Product Description

The detailed process of animal feed pellet production line:

Step 1. Raw materials receiving and cleaning process- (drum sieving precleaner, conical powder sieve and peermanent magnetic drum). Drum sieving precleaner is used to clean and sort out the big debris such as corn stalk, stones, rope head, branches, corn cobs and the small debris such as mud, sand and blighted grain. When the raw materials are powder, conical powder sieve is used to clean the debris in the powder. (And the machine can also be used after the mixing process and before the pellet making process to make sure the pellet mill can be smooth operation).

Step 2. Crushing process---hammer mills We have many kinds of hammer mills for your choice: water drop hammer mill, multifunctional hammer mill and 9fq hammer mill etc. This process is mainly used to crush to raw materials into powder.

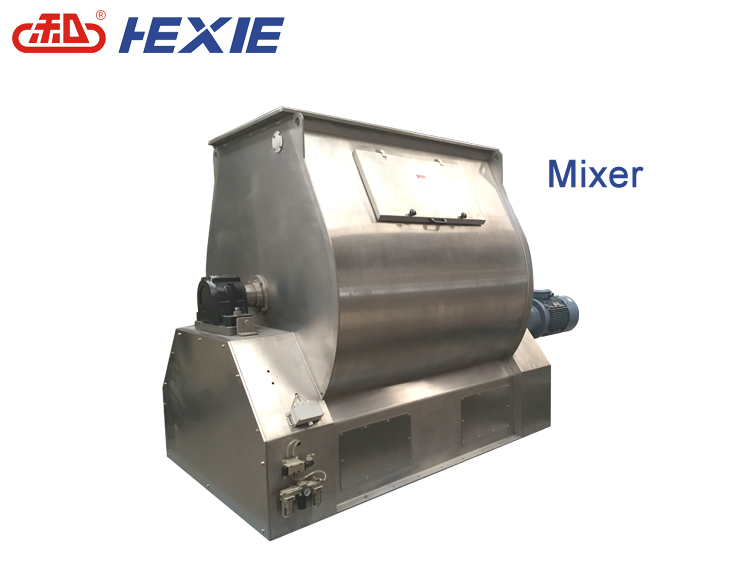

Step 3. Mixing process---feed mixer The feed mixer we have are single shaft double screw mixer, double shaft paddle mixer, vertical mixer. The process is used to mixed the crushed materials with higher uniformity.

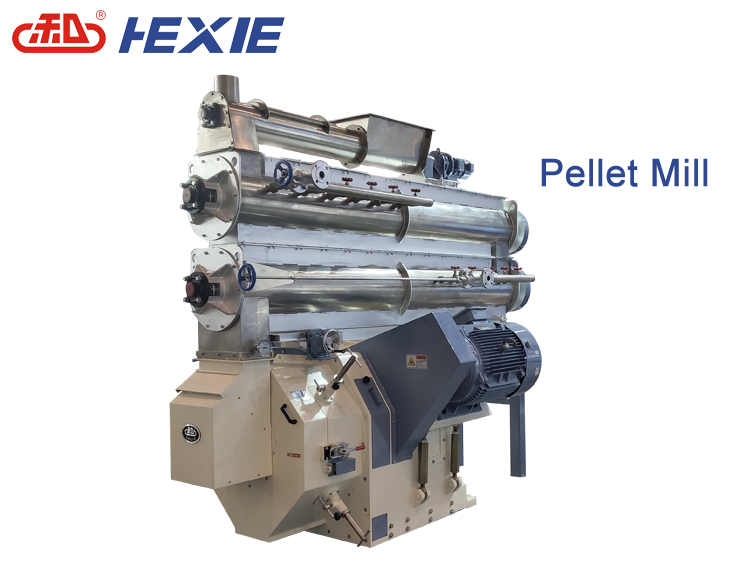

Step 4. Pellet making process---feed pellet mill We have five models of feed pellet mill for your choice. This process is to press the pellets out.

Step 5. Pellet cooling process---counter flow cooler The newly pressed pellets are very high in temperature. This process is to cool the pellets to ±3-5℃ of the room temperature.

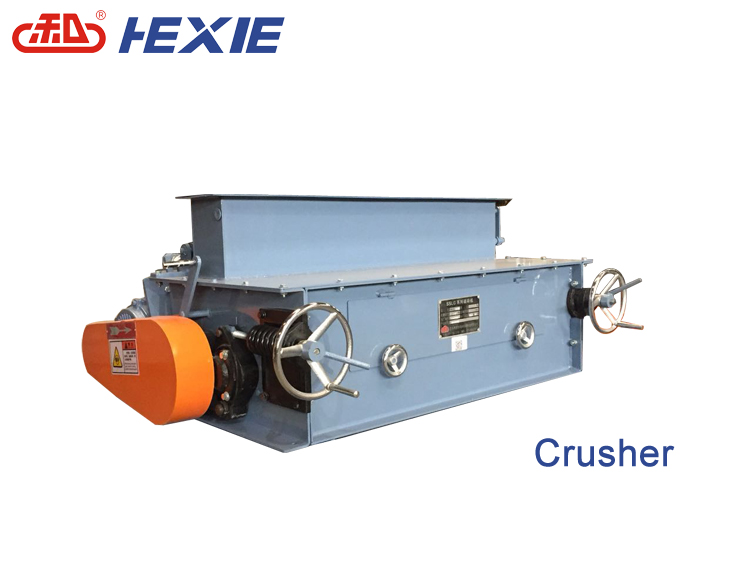

Step 6. Pellet crumbling process----feed crumbler (roller crusher) This process is mainly to crush the big pellets into small ones. It is mainly used for chicken feed pellet line.

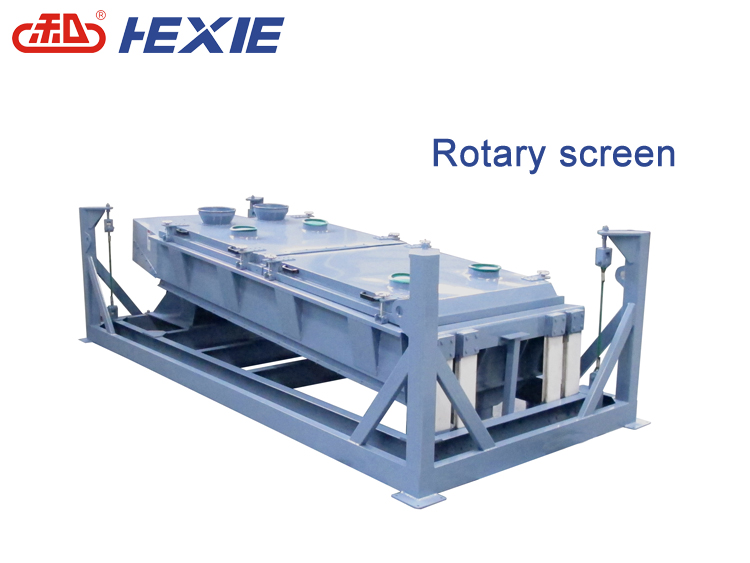

Step 7. Sifting process--vibratory sizing sieve and plenary rotary sizing sieve This process is mainly to sort out the inappropriate pellets and powder and send the standard pellets to next process.

Step 8. Packing process -----packaging machine This process is to pack the pellets into bags which is convenient for storage and transportation.

Tips for pelleting Animal Feed

Animal Feed contains high amount of grains and that means high concentration of fiber. Good quality of pre-conditioning is the key of success in making chicken pellet feed. Enough direct and indirect steam heat source and moisture will soften the mash with high elasticity. Gelatinized starch is the perfect binder to form pellets.

Too much fat added in the formulation will create high amount of fines formation during pelleting. It is suggested to add 1% of fat in the mixer and this will lower the wear on the dies and improves the throughput of the pellet mill. Any additional fat is suggested to evenly spray on the pellets to improve the fat contents and quality of the pellet surface.

Pellet size are from 2.0mm, 3.0mm, 3.5mm, 4.5mm to maximum 18.0mm

If you are insterested in our machines, pls contact with us and tell us the

following questions :

The capacity you need ? Your raw material ?

Our engineer will design it according to your requirement .

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier