TPHD2016 HIGH SPEED DRILLING MACHINE FOR PLATE

- Product Details

- Company Profile

TPHD2016 HIGH SPEED DRILLING MACHINE FOR PLATE

- 1. CNC slide way drilling spindle (Z axis) with work piece of stroke is pre-set, realized auto switch. It can drill not only through-hole, but also blind-hole with high efficiency, simple-structure, low-cost maintenance, easy operation etc.

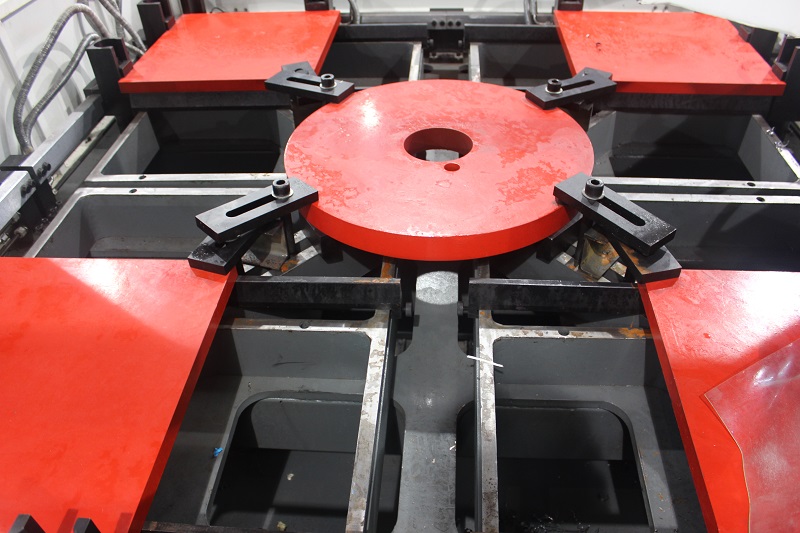

- 2. There are 12 hydraulic clamps & T slots for fixing workpieces, easy to operate, also save time, improve production efficiency.

- 3. This machine have three CNC axis: gantry moving direction (x-axis);drilling head moving direction (y-axis); Spindle feeding direction (z axis). Machine equip each axis with linear guide and ball screw which drived by high precision servo motor.

- 4. Machine have scrap cleaner which collect iron scraps and cutting liquid.

- 5. The machine equipped with automatic lubrication system for linear guides and ball screws.

- 6. Machine adopts SIEMENS 808D system, also equip with computer for drawing and workpiece program processing, easy to operate.

- 7. The configuration of the machine, like ball screws, linear guides, main electrical parts, servo motors, inverter, etc., all famous brands.

Model

TPHD2016

Max work piece size (L×W)

2000x1600mm plate or Φ1600mm flange

Thickness of work piece

6--120mm

Drill unit type

sliding table, servo control

Drill head quantity

ATC (Automatic Tool Change -8 pics tools)

Spindle motor power

22 kW

Max drill diameter

Φ50mm

Taper hole of spindle

BT50

Spindle speed

30~3000r/min

Spindle vertical stoke (Z axis)

300mm

Servo motor power of X axis

2.0 kW

Servo motor power of Y axis

1. 5 kW

Servo motor power of Z axis

2.0 kW

Motor power of scrap cleaner

0.75 kW

Clamping type

12 Hydraulic clams and T-slot

Electric control type

SIEMENS 808D

CNC axis quantity

3

Position precision

±0.08mm

With function of CAD/CAM automatic generation

With function of break point memory (Restart production easily after power off)

Overall size

About 4900x3900x3200

Weight

About 14000

Experience Member

Experience Member 0

0 Chinese

Supplier

Chinese

Supplier