Model HTK-07C02 RFID Reader in Association with VEIC HABD System

- Product Details

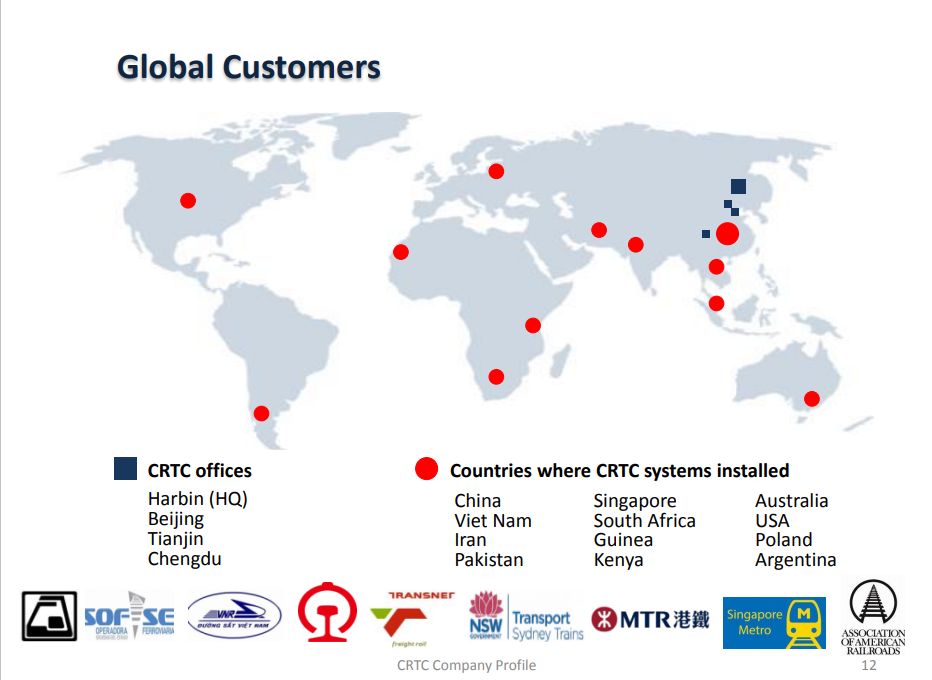

- Company Profile

HTK-07C02 RFID reader is specially designed to work with VEIC HTK-499 and THDS Hot Axle Box Detector System. With integration of the RFID reader, wagons number will be combined with bearings temperature report on real time basis. This combination will help HABD system to locate any hot bearing by wagon number as well as axle number on the wagon.

HTK-07C02 RFID reader is specially designed to work with VEIC HTK-499 and THDS Hot Axle Box Detector System. With integration of the RFID reader, wagons number will be combined with bearings temperature report on real time basis. This combination will help HABD system to locate any hot bearing by wagon number as well as axle number on the wagon.

The reader consists of:

Trackside equipment including an RFID antenna, a coaxial cable and a junction box (optional as coaxial cable can come into cabinet directly)

1. Features

? Solid and compact: HTK RFID reader is all-in-one unit with only 1U height which can be fixed into the same cabinet of VEIC HTK-499 or THDS HABD without requiring additional space.

? Wagons number are read and processed while HABD is measuring bearings temperature. The decoded wagon tags information will be sent to HABD system on real time basis so that HTK-499 or THDS detector computer is able to process the tags information simultaneously when it processes bearing data. This will ensure accurate and reliable matching between wagons number and bearings temperature. Error even failure may occur when doing the matching later on at elsewhere than at site.

? Environment friendly: HTK RFID reader omits radio frequency only when a train is passing the site. It stays in sleep while the track is vacant.

? Working under harsh environment: HTK RFID reader is against EMI, extreme climates and shock & vibration.

Working temperature: -25℃~+70℃

Relative humidity: < 95% (under ambient temperature at 40℃)

Power supply: AC220V±15%,50Hz±1 Hz

2. Performance and Specifications

? RF’s transmittance can be triggered by external signal;

? Read transportation tag information encoded in either FSK or FM0 format;

? Tag data is transferred on real time basis;

? Indicating lights are provided on RFID reader to show status of RF transmitting, tag reading, data TX and RX etc.;

? RF transmitting power: 0.8W ~ 1.6W;

? RF range: 902MHz ~ 928MHz;

? Resistant: 50 Ohm;

? Gain of antenna: 8.6dB ~ 9.6dB;

? Tag reading distance: 0 ~ 2.4 meter (along the train moving direction);

? Train speed range: 0 ~ 350 Km/h;

? Data transfer port: DB9 (RS-232);

? Data transfer rate: 28800 bps.

3. Operation

5.1 How RFID reader works

1) When a train is approaching, RF module is triggered by external signal to transmit radio frequency through antenna;

2) During the train passing through the site, energized tags (by radio frequency) send modulated information stored in the tags to antenna. The information will then be send to RFID reader through coaxial cable. RFID reader will demodulate, decode, verify and record the information. Finally, the so processed tag information is send to HTK or THDS detector computer for combination with bearings data.

3) After the train passed away from the site, RF reader will receive an external signal to shut down transmittance of radio frequency.

4) The external signal to trigger and shut down the reader is sent from HTK or THDS system.

Front and back panel of RFID reader

Fig. 3 Front view of RFID reader

Fig. 4 Back view of RFID reader

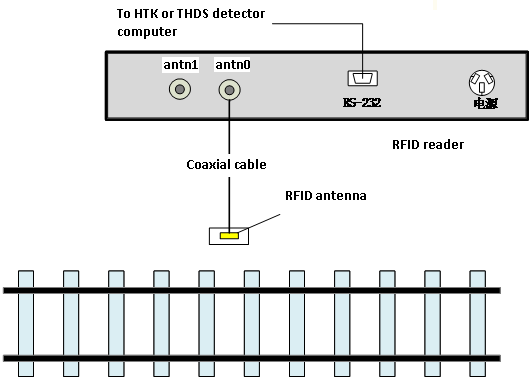

Installation

The coaxial cable’s maximum length is 25 meter. It can’t be twisted and L bent when doing installation.

Below figure shows the layout of installation

Fig. 5 Layout of RFID reader installation

The installation is easy. After fixed the antenna, fix the RFID reader into the cabinet and connect coaxial cable between the antenna and port anta0 on back panel. Also connect a serial port cable between detector computer and RS-232 on back panel.

The coaxial cable shall be protected by rubber hose and coaxial cable’s connector should be properly fastened.

Free Member

Free Member 0

0 Chinese

Supplier

Chinese

Supplier