Supplier Recommended by CCCME

Supplier Recommended by CCCME

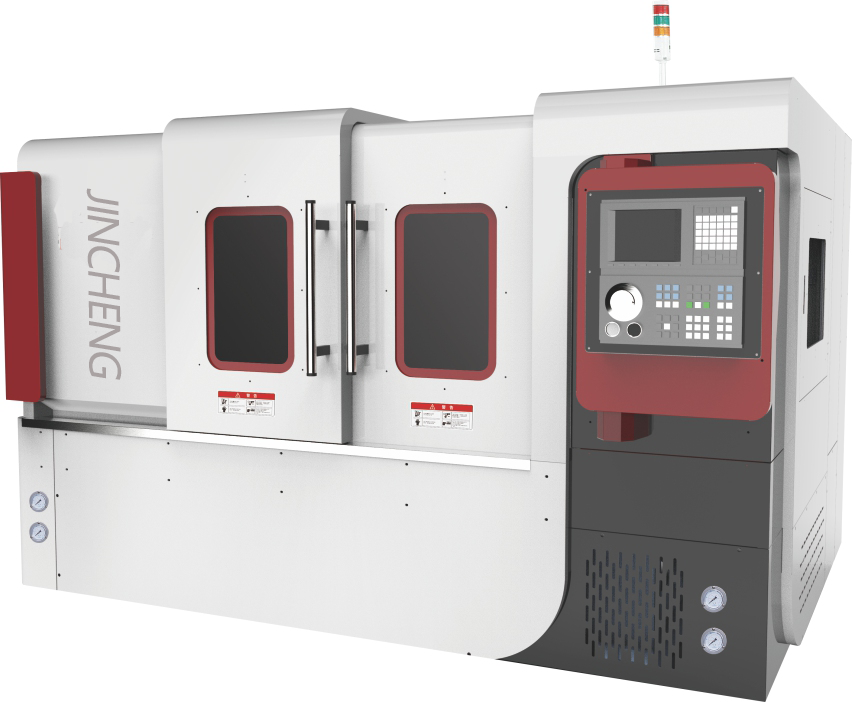

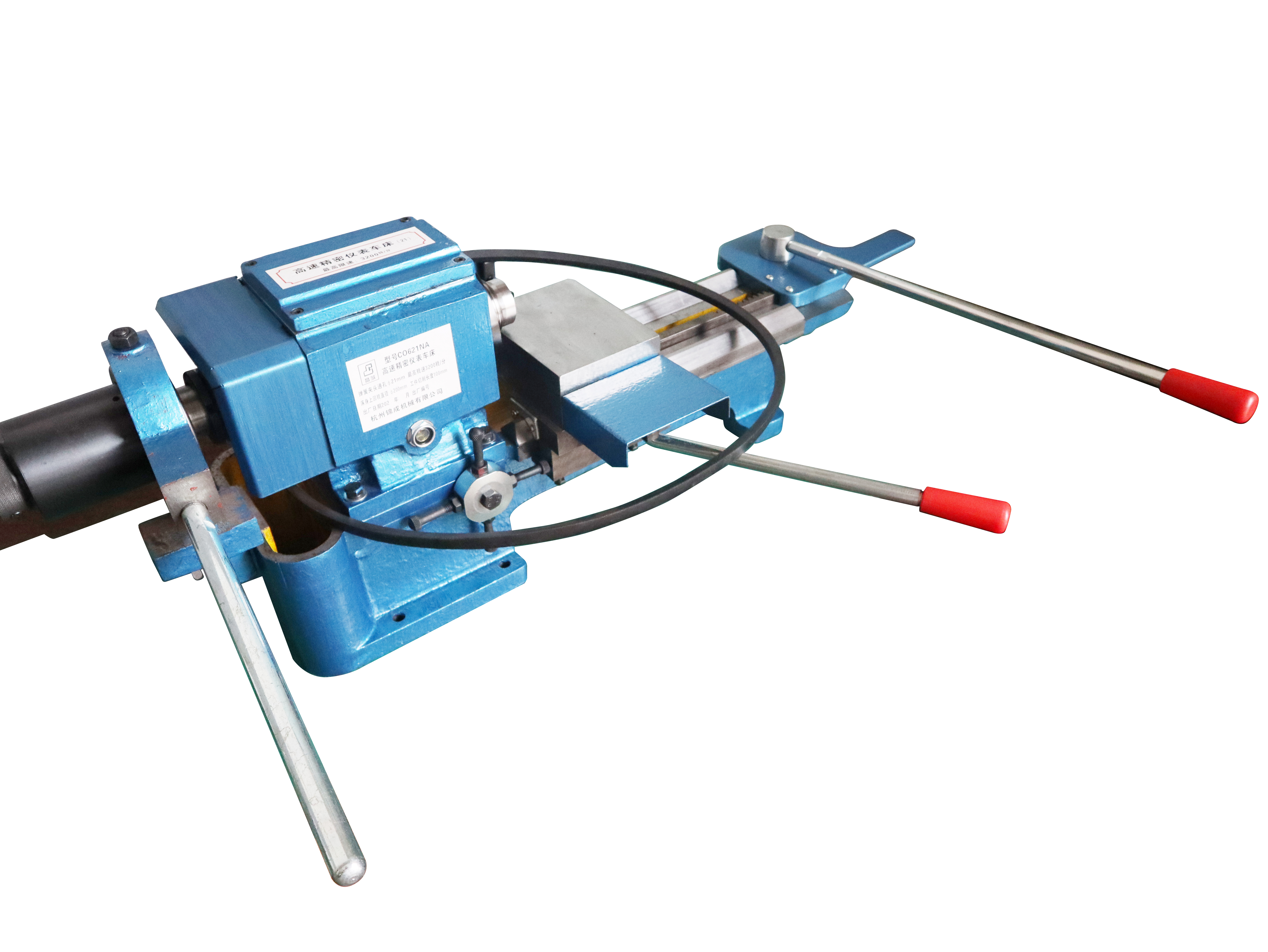

Hangzhou Jincheng Machinery Co., Ltd., established in 2005 and situated in Xiaoshan, Hangzhou, is a national high-tech enterprise. With years of in-depth engagement in the CNC equipment sector, the company takes technological innovation as its core driving force and customer-oriented diversified processing needs as its guide. It is dedicated to providing high-quality CNC equipment and comprehensive technical services for the manufacturing industry, facilitating the intelligent and efficient transformation of the sector. The company's core business encompasses the R&D and production of CNC lathes, customization of mid-to-high-end CNC equipment, supply of supporting automated equipment, and maintenance services for CNC machine tools, forming a full-chain service system of "R&D - Production - Supporting - Operation and Maintenance". In the R&D of core products, the company focuses on the mid-to-high-end CNC lathe segment, specializing in the development of high-precision equipment such as turn-mill compound machines and double-head docking equipment. Leveraging independent core technologies (with dozens of core technology patents), it realizes multi-process machining including turning, milling, drilling and tapping of workpieces with one-time clamping. The equipment precision fully meets various processing requirements of customers, effectively improving processing accuracy and production efficiency, resolving the pain points of cumbersome processes and high error rates in traditional processing modes. Relying on high-quality products and services, the company has established in-depth cooperation with well-known auto parts enterprises such as Ningbo Zhong'an Casting, Zhejiang Zhengqiang, and Zhejiang Wanxiang Precision. Its products are applicable to high-end manufacturing scenarios including auto parts and precision electronics. Meanwhile, the company provides popular CNC equipment, and its instrument lathes, featuring stable and reliable performance, meet the basic needs of small and medium-batch processing, forming a product matrix covering high, medium and low-end markets. To assist enterprises in achieving automated production upgrading, the company has specially developed lathe-matched collaborative manipulators. Through precise motion control and flexible adaptive design, it realizes the automation of processes such as machine tool loading and unloading and workpiece transfer, reducing manual intervention, lowering production costs, shortening the investment return cycle, and providing core support for customers in constructing unmanned production units. In the field of technical services, the company has established a professional maintenance team with rich experience and exquisite skills, providing comprehensive maintenance services for both domestic and imported CNC machine tools. Adhering to the service philosophy of "prevention first and rapid response", the company not only offers customers emergency fault maintenance, equipment overhaul, and upgrading and transformation services but also launches preventive maintenance services such as regular inspections, precision calibration, and maintenance training. It establishes an exclusive maintenance file for each piece of equipment to ensure that the equipment maintains an optimal operating state at all times. For sudden faults, the company provides 24-hour technical support, combining remote diagnosis and on-site services to quickly resolve equipment issues and minimize production downtime losses. As a national high-tech enterprise, Jincheng Machinery has always attached great importance to investment in technological R&D. It has gathered top technical talents in the industry, established a professional R&D team, and continuously promoted technological innovation and product iteration. The company owns dozens of core technology patents, and many of its technological achievements have been recognized by the industry. With an annual output value of 20 million yuan, the company has gained wide market trust by virtue of its solid technical strength and stable production capacity, and its equipment precision fully meets the actual production needs of customers. Adhering to the business philosophy of "quality-oriented and integrity-based", the company strictly controls every link in the production process, establishing multi-dimensional quality inspection standards from raw material procurement to product delivery, so as to ensure that each piece of equipment delivered to customers meets high-quality requirements. In the future, Hangzhou Jincheng Machinery Co., Ltd. will continue to deepen its involvement in the CNC equipment field, focus on the development trend of intelligent manufacturing, continuously enhance its core technological competitiveness, expand the boundaries of automated and intelligent products and services, and work hand in hand with customers to contribute to promoting the high-quality development of China's manufacturing industry.